Zhejiang Jhenten Machinery Co.,Ltd.

Name:Henson.Zeng

Phone:+86 15957782988

Tel:+86 577-86867777

Email:info@jhenten.com

No.808 Haitong Road, Binhai Development Zone, Wenzhou City

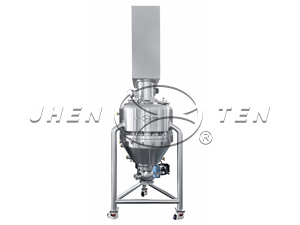

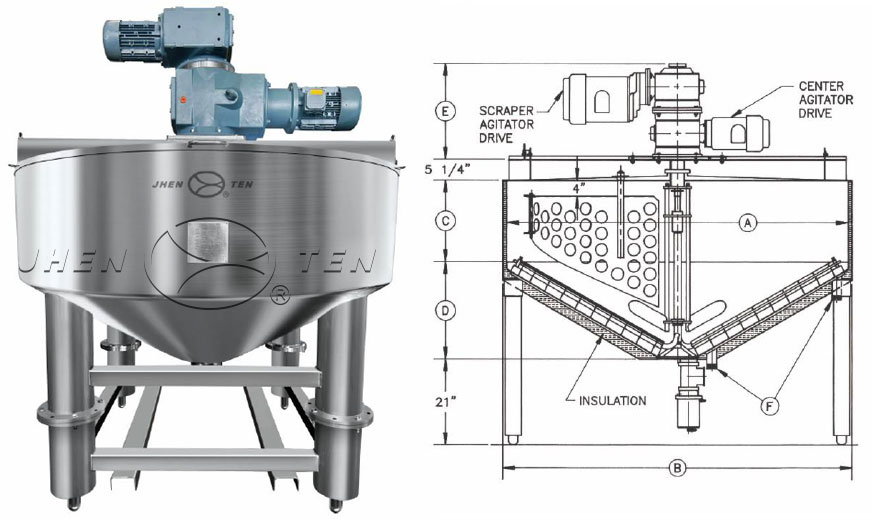

Mixing tank

Scrarer cooker cooler

Our double scraper cooker has the functions of fast heating, keeping warm, cooling, mixing and so on.

Introduce

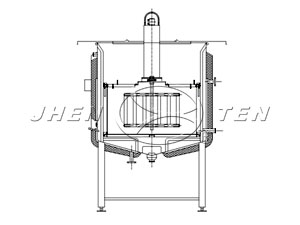

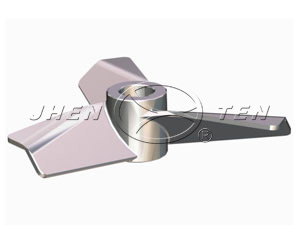

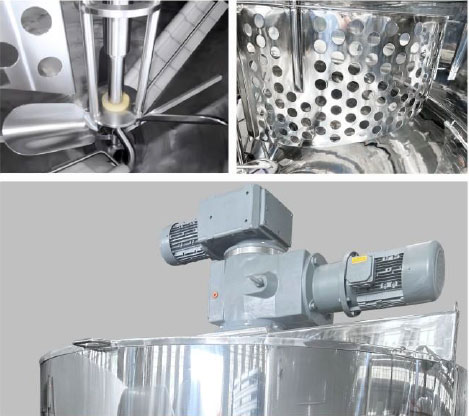

Our double scraper cooker has the functions of fastheating, keeping warm, cooling, mixing and so on. It consists of a cylindricalbody, cone-shaped bottom and 4 supporting legs. Designed with a jacket on itssidewalls and bottom, coupled with the use of full-scraped surface anddual-motion counter- rotating agitator, assures the products can be heated andcooled extremely fast.

Application

Used for the processing of various kinds offood, specially used in large restaurant or dining room to boil soup, cook,stew, boil congee, etc. Used in liquid configuration, soup and concentrationin pharmaceutical, food, chemical industry and light industry.

Feature

◆Jacketed kettle have large heatingarea, high thermal efficiency, even heating advantage, short boiling time andeasy control of heating temperature. It is a good equipment to improve quality,shorten time and improve working conditions on food processing.

◆Volume: from 25gal to 800gal andmultiple specification, we can design and manufacture according to customer'srequirement as well.

◆The connection adopts Tri-clamp,the tanks inner use ss304 or ss316L. The inner surface mirror polishingRa≤0.28μm. Outer surface can bepolished, sandblasted, satin as customer's requirement.

Date Specifications of Scraper Agitator Drive

Model JTSCC-25 | ½ HP | 30 RPM |

Model JTSCC-50 | 1 HP | 30 RPM |

Model JTSCC-100 | 1½ HP | 20 RPM |

Model JTSCC-200 | 2 HP | 20 RPM |

Model JTSCC-400 | 3 HP | 20 RPM |

Model JTSCC-800 | 5 HP | 20 RPM |

Date Specifications of Center Agitator Drive

Model JTSCC-25 | ¾HP | 90RPM |

Model JTSCC-50 | 1 HP | 90 RPM |

Model JTSCC-100 | 1½ HP | 90 RPM |

Model JTSCC-200 | 1½ HP | 90RPM |

Model JTSCC-400 | 1½ HP | 90RPM |

Model JTSCC-800 | 3 HP | 90RPM |

Design Parameter

Design pressure | According to customers’ requirement(ATM~1.0Mpa) |

Design temperature | According to customers’ requirement(0℃~250℃) |

Material

Kettle liner | 304、316L |

Kettleoutlet layer | 304 |

Legs | 304 |

Connection

In-outlet | Tri-clamp,Flange |

Surface Finish

Finish type | echanical/electrolytic polishing, sand blasting, pickling |

Polishingprecision | Inner surface Ra≤ 0.4μm, Outside surface Ra≤ 0.6μm |

Date Specifications

Model | JTSCC-25 | JTSCC-50 | JTSCC-100 | JTSCC-200 | JTSCC-400 | JTSCC-800 |

Working CapacityGal. | 25 | 50 | 100 | 200 | 400 | 800 |

Full CapacityGal. | 76 | 116 | 206 | 367 | 642 | 1025 |

A- inches (I.D.) | 36 | 48 | 60 | 72 | 84 | 84 |

B- inches (O.D.) | 38 | 50 | 62 | 74 | 86 | 86 |

C- inches | 14 | 11 | 12 | 15 | 20 | 35 |

D- inches | 9 ¼ | 12 | 15 3/8 | 19 5/8 | 23 7/8 | 23 7/8 |

E- inches | 15 7/8 | 20 1/16 | 20 1/8 | 20 1/8 | 23 9/16 | 31 |

F- MTP Size | 1½ | 1½ | 2 | 2 | 2 | 2 |

Weight- Pounds | 850 | 1760 | 2150 | 2450 | 3560 | 4300 |

L.B./H.R. Steam(Nominal) | 200 | 337 | 610 | 1080 | 2000 | 2000 |

| Full Load Amps | ||||||

| 230V | 5.6 | 8 | 11 | 13 | 16 | 23.4 |

| 460V | 2.6 | 4 | 5.5 | 6.5 | 8 | 11.7 |

- PrevVacuum Spherical Mixing Kettle

- NextNO!

Welcome to send an online inquiry! If you have any suggestions or questions about our products, you can Email us.info@jhenten.com, also feedback through this inquiry; we will reply to you within 24 hours. (Monday to Friday, 9:00-17:30)

Other Products

We focus on the sanitary pressure vessels, process tanks and modular system design and manufacture.