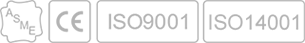

Zhejiang Jhenten Machinery Co.,Ltd.

Name:Henson.Zeng

Phone:+86 15957782988

Tel:+86 577-86867777

Email:info@jhenten.com

No.808 Haitong Road, Binhai Development Zone, Wenzhou City

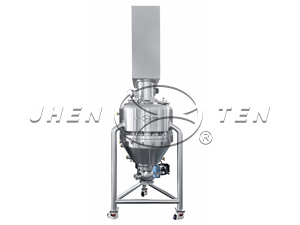

Mixing tank

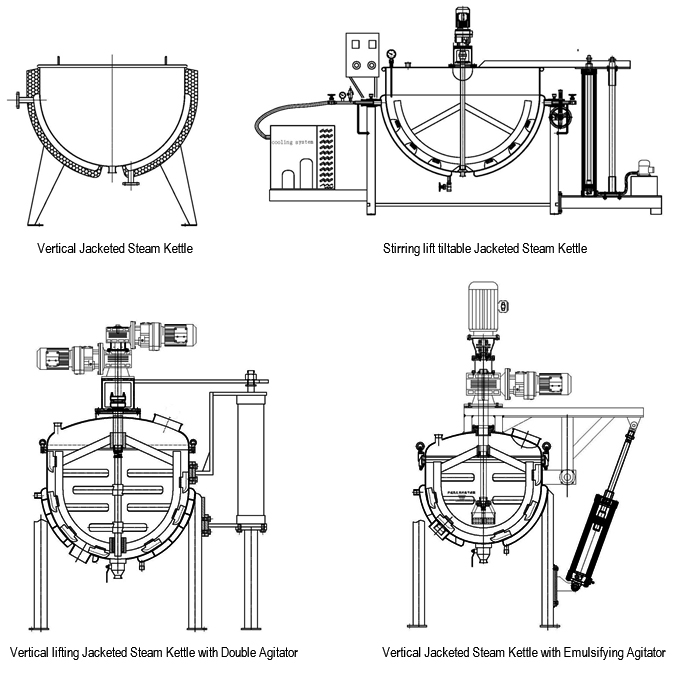

Jacketed Steam Kettle

Model: JTRZG

Brand: JHENTEN

Jacketed Steam Kettle is designed, manufactured and inspected in accordance with the pressure vessel standard(GB150-2011) and the steel welded atmospheric pressure vessel standard(NB/T 47003.1-2009) , strictly meeting to GMP certificate requirements.

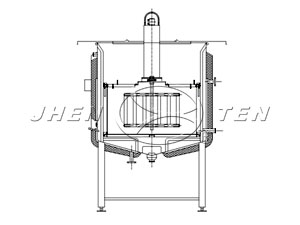

Steam kettle have double-layer structure, and jacket uses steam or heat conduction oil as a heating medium. Steam kettle can use installed flange discharge, and material can be directly discharging after steaming. It is a convenient operation. Kettle body adopts circular arc transition, no dead corner, easy to clean; mirror polishing processing meets sanitary standard.

Jacket kettle can be fixed structure or tiltable structure, also can add mixing device and emulsification device according to customers’ requirements.

Tank Optional Configuration

Jacketed Steam Kettle can configure thermometer(Digital display or Dial type), pressure gauge, sight glasses, sanitary manhole, liquid in-outlet, CIP cleaning ball and so on, also can configure as customers’ requirement.

Feature

• Jacketed kettle have large heating area, high thermal efficiency, even heating advantage, short boiling time and easy control of heating temperature. It is a good equipment to improve quality, shorten time and improve working conditions on food processing.

• Volume:50L~500L and multiple specification, also we can design and manufacture according to customers’ requirement.

• The connection adopts Tri-clamp, the tanks’ inner use 304 or 316L. The inner surface mirror polishing Ra≤0.28μm~0.6μm. Outer surface can be polished, wiredrawn, sandblasted according to customer's requirement.

Application

• Used for the processing of various kinds of food, specially used in large restaurant or dining room to boil soup, cook, stew, boil congee, etc.

• Used in liquid configuration, decoction and concentration in pharmaceutical, food, chemical industry and light industry.

Design Parameter

Designpressure | ATM~1.0MPa |

Designtemperature | 0℃~250℃ |

Surface Finish

Finishtype |

Mechanical/electrolyticpolishing, |

Polishingprecision |

Innersurface Ra≤ 0.4μm, |

Material

KettleLiner | 304、316L |

Kettleouter layer | 304 |

Feet | 304 |

Connection

In-outlet | Tri-clamp,Flange |

Structure

Normal Model And Main Technical Parameters

Parameters | Model | JTRZG—50 | JTRZG—100 | JTRZG—200 | JTRZG—300 | JTRZG—400 | JTRZG—500 | |

Effective volume:L | 50 | 100 | 200 | 300 | 400 | 500 | ||

Evaporation:Kg/h(Rinsing) | 30 | 40 | 65 | 75 | 100 | 150 | ||

Heat-transfer area:m2 | 0.40 | 0.60 | 1.00 | 1.44 | 1.65 | 1.90 | ||

Steam consumption:Kg/h | 33 | 44 | 72 | 110 | 136 | 165 | ||

Kettle | Diameter:mm | Φ600 | Φ700 | Φ800 | Φ900 | Φ1000 | Φ1100 | |

Kettle depth:mm | 450 | 520 | 550 | 630 | 680 | 750 | ||

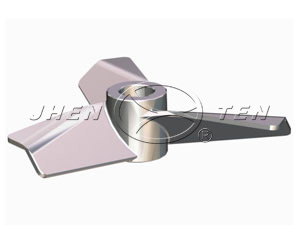

Agitator | Power:kW | 0.37 | 0.37 | 0.55 | 0.75 | 0.75 | 1.1 | |

Agitator RPM:r/min | 36(Can adjust thedesign according to the customer’s usage) | |||||||

Emulsification | Power:kW | 1.1 | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | |

Emulsifyingspeed | 4P(Can adjust thedesign according to the customer’s usage) | |||||||

Structure | Fixed(Vertical or horizontal)/tiltable/mixing | |||||||

The above-mentioned data is the standard for vertical Jacketed SteamKettle (Emulsifying stirring type), the capacity, jacket operate pressure,power and agitator structure can be customized according to customers’requirements.

Welcome to send an online inquiry! If you have any suggestions or questions about our products, you can Email us.info@jhenten.com, also feedback through this inquiry; we will reply to you within 24 hours. (Monday to Friday, 9:00-17:30)

Other Products

We focus on the sanitary pressure vessels, process tanks and modular system design and manufacture.