Zhejiang Jhenten Machinery Co.,Ltd.

Name:Henson.Zeng

Phone:+86 15957782988

Tel:+86 577-86867777

Email:info@jhenten.com

No.808 Haitong Road, Binhai Development Zone, Wenzhou City

Evaporative concentrator

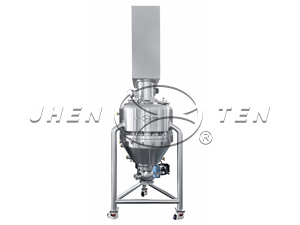

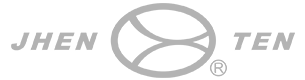

CONTINUOUS EVAPORATION CRYSTALLIZER

Crystal slurry circulating continuous crystallzer. Operation, liquid from the lower circulation pipe to join and leave the crystal room at the bottem of the crystal slurry mixture sent to the heating chamber by the pump.

Continuous Evaporation Crystallizer

Crystal slurry circulating continuous crystallzer. Operation, liquid from the lower circulation pipe to join and leave the crystal room at the bottem of the crystal slurry mixture sent to the heating chamber by the pump. Crystal slurry temperature in heating room (usually 2~6°C), but evaporation dose not occur. Hot plasma into the Crystal Room Crystal after boiling, the solution had reached saturation,so part of the solute in the suspened sediment grain surface,the crystals grow. As the product of the crystal slurry discharged from the upper circlar tube. Forced circulation evap

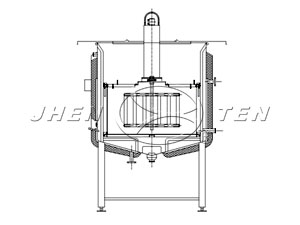

DTB Evaporator Crystallizer

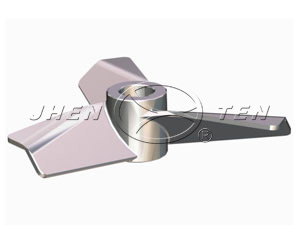

The draft tube-mold baffle evaporation. but also a crystal slurry circulating mold Elutriation device then there is the lower column, the device features a draft tube and the cylindrical baffle, operation,seturated liquid heat circution pipe added to the lower part of a continuous, circular tube with a small crystal mother liquor entrained mixture pumped to the heater. The heating of the solution near the bottom of the draft tube into the mold by slowly rotating propellers sent along the draft tube surface. Solution in the liquid cooling, up to over saturation,some of wich solute particles in the suspension deposited on the surface, so that the crystal growth. Outside the ring bezel and a Settlement arae. Settlement of large particals in the settlement area, while the small particles into the circulation pipe is with the mother liquor and heated todissolve. Crystal at the bottom of the mold into the elutriation column. To crystallize the product size as even as possible part of the settlement area to the mother liquor added to the bottom of the elutiation column.the use of hydraulic grade effct in that the return flow of small particles with the mold, and mold products discharged from the lower partof elutriation column Out.

Welcome to send an online inquiry! If you have any suggestions or questions about our products, you can Email us.info@jhenten.com, also feedback through this inquiry; we will reply to you within 24 hours. (Monday to Friday, 9:00-17:30)

Other Products

We focus on the sanitary pressure vessels, process tanks and modular system design and manufacture.