Welcome to the 'Online Message' section! If you have any suggestions or questions about our products, please feel free to provide us with feedback through this section.

We will reply to you within 24 hours.

Ultra-Gentle Processing

Precision Temperature & Efficiency

Complete Hygiene & Safety

Robust Long-Term Durability

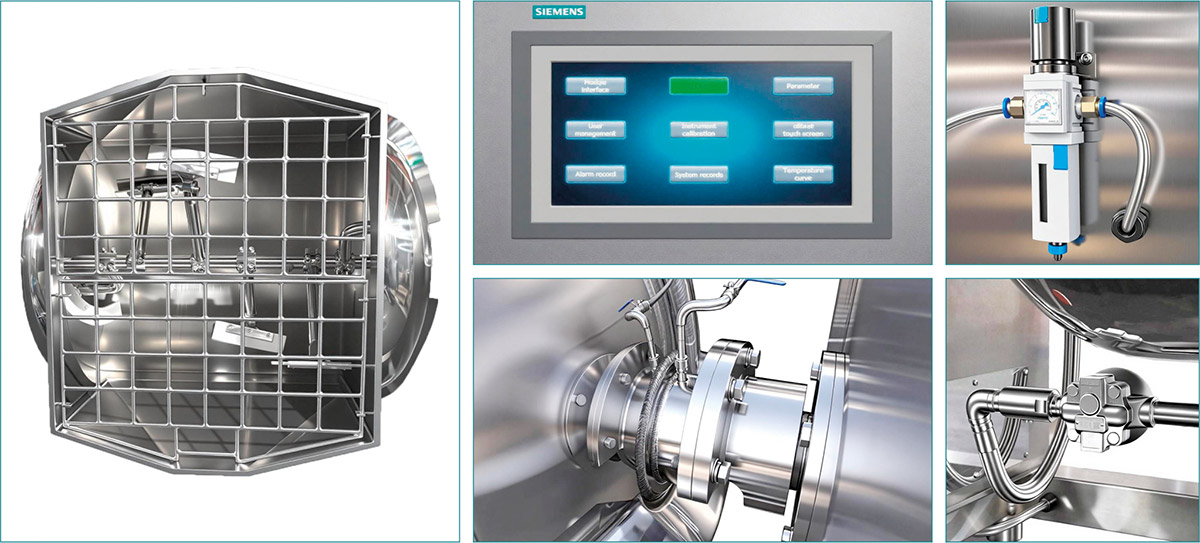

Steam Jacketed Vessel

·Steam heating for easy thermal control and simplified cleaning/maintenance.

·High-efficiency steam pressure (3.0 kg/cm2) for high-temperature processing.

·Full jacket with deflector plate design.

Temperature Control Module

·Feedback control system + steam recovery pipeline reduces energy consumption by 30%.

Mixing System

·PTFE/PEEK available optional blade material.

·Dual-motion (revolution + rotation).

·Variable frequency speed regulation (5-60 rpm adjustable).

Tilt Discharge

·Hydraulically-driven 70°tilting for residue-free discharge.

·Different grades of hydraulic systems can be optionally equipped.

Intelligent Control

·PLC touchscreen interface.

·Pre-set process curves.

·Real-time monitoring (temperature/speed/time parameters).

Tilting Discharge System

Optional weighing module

Frame Structure

Ultra-Gentle Processing

Unique semi-cylindrical vessel + flexible PTFE paddles simulate natural material flow, achieving >99% particle integrity.

Precision Temperature & Efficiency

Dual steam injection/recovery system boosts thermal efficiency by 40%, enabling continuous 120°C high-temperature operations.

Complete Hygiene & Safety

Full food-grade construction (SUS 304/316L + PTFE), No sanitary dead corners, supports CIP (Clean-in-Place), and meets FDA certification requirements.

Complete Hygiene & Safety

Frequency conversion speed control can be used to match material viscosity, and can be equipped with process memory and remote IoT functions.

Robust Long-Term Durability

Reinforced stainless steel body with ≥10-year design lifespan.

·Vacuum Series: Prevents oxidation during foaming (ideal for jams/creams).

·Cooling Type: Rapid cooling through jacket with cold water circulation (suits jellies/gel-based products).

·EX-Proof Configuration: Designed for flammable materials (optimized for alcohol-based sauces).

·Specialized Paddles: Anchor type / Impeller type (for ultra-high-viscosity materials).

| Model | JTWZG-300 | JTWZG-500 | JTWZG-600 | |

|---|---|---|---|---|

| Tank capacity (L) | 300 | 500 | 620 | |

| Mixing motor (KW) | 1.5 | 2.2 | 2.2 | |

| Maximum steam pressure | 0.3MPa | 0.3MPa | 0.3MPa | |

| Steam consumption (initial/average) (kg/h) | 220/150 | 310/210 | 340/240 | |

| Boiling (KW) | 0.7 | 1.13 | 1.13 | |

| Dimensions (mm) | L | 2950 | 3150 | 3200 |

| W | 1185 | 1235 | 1400 | |

| H | 1735 | 1820 | 1975 | |

Specifications other than the above dimensions can also be customized.