Welcome to the 'Online Message' section! If you have any suggestions or questions about our products, please feel free to provide us with feedback through this section.

We will reply to you within 24 hours.

Efficient Space Utilization

Precise Thermal Penetration

Ultimate Hygiene Assurance

Smart Flexible Production

Industrial-grade Durability Design

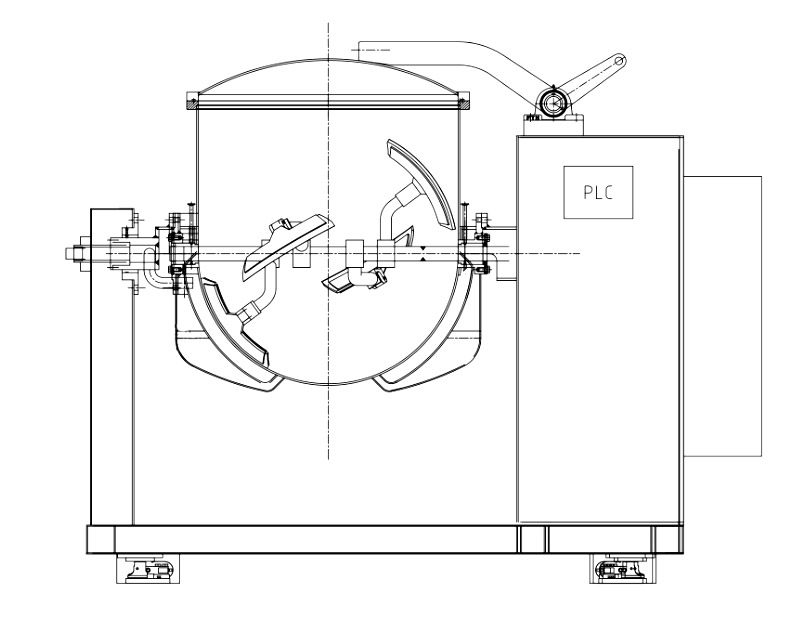

Vertical Steam Kettle Body

·Compact vertical design saves floor space.

·Jacket steam direct injection (3.0 kg/cm2 pressure) enables 120℃ uniform heat penetration.

·Full jacket with deflector plate design.

Energy-saving Temperature Control Module

·Intelligent PID temperature control + secondary steam recovery reduces overall energy consumption.

·Automatic condensate discharge prevents thermal efficiency decay.

Vertical Mixing System

·SUS 316L + PTFE composite anchor-type blades.

·Bidirectional variable-frequency mixing supports stepless speed regulation.

·Bottom anti-sedimentation scraper design suitable for high-viscosity materials.

Condensate recovery unit

Aseptic Discharge Design

·Pneumatically controlled quick-opening bottom valve ensures residue-free opening/closing.

·Optional sanitary butterfly/ball valve meets GMP standards for closed discharge.

Intelligent Control Center

·Industrial touch-screen PLC.

·Customizable process recipe storage.

·Real-time monitoring of temperature, pressure, speed, and liquid level.

Steam heating jacket

Optional weighing module

Bottom discharge valve system

Reinforced support base

Efficient Space Utilization

Vertical structure reduces horizontal footprint by 60%, ideal for compact workshops, increasing production density.

Precise Thermal Penetration

Enveloping steam jacket heating ensures uniform material heating with no localized scorching risk.

Ultimate Hygiene Assurance

Mirror finish on all contact surfaces, dead-angle-free CIP/SIP cleaning, FDA/CE certified.

Smart Flexible Production

·Mixing torque automatically adapts to material viscosity changes.

·Optional weighing module for MES system integration.

Industrial-grade Durability Design

·Thickened stainless steel cylinder.

·Premium seals with lifetime warranty.

·Design life ≥10 years.

| Model | JTQXG-100 | JTQXG-200 | JTQXG-500 | JTQXG-800 | JTQXG-1100 | JTQXG-2000 | JTQXG-2400 | |

|---|---|---|---|---|---|---|---|---|

| Full water capacity (L) | 100 | 200 | 500 | 800 | 1100 | 2000 | 2400 | |

| Mixing motor (KW) | 0.75 | 0.75 | 2.2 | 3.7 | 3.7 | 7.5 | 11 | |

| Maximum working pressure of steam | 3.0kg/cm² | 3.0kg/cm² | 3.0kg/cm² | 3.0kg/cm² | 3.0kg/cm² | 3.0kg/cm² | 3.0kg/cm² | |

| Steam consumption (kg/h) | 70 | 105 | 150 | 220 | 235 | 250 | 315 | |

| Cylinder tilt (KW) | 0.2 | 0.2 | 0.4 | 0.4 | 0.4 | 0.75 | 1.5 | |

| Cover opening and closing (KW) | 0.2 | 0.2 | 0.2 | 0.4 | 0.4 | 0.4 | 0.4 | |

| Vacuum pump (KW) | 1.5 | 2.2 | 3.7 | 7.5 | 7.5 | 7.5 | 15 | |

| Vacuum pump installation space (mm) | 400×650 | 450×700 | 600×940 | 630×1120 | 630×1120 | 630×1120 | 700×1300 | |

| Dimensions (mm) | L | 1550 | 1850 | 2200 | 2730 | 3050 | 3500 | 3850 |

| W | 840 | 930 | 1100 | 1260 | 1450 | 1520 | 1750 | |

| H | 1435 | 1575 | 1765 | 1970 | 2330 | 2530 | 3755 | |

Specifications other than the above dimensions can also be customized.