Welcome to the 'Online Message' section! If you have any suggestions or questions about our products, please feel free to provide us with feedback through this section.

We will reply to you within 24 hours.

·Energy Saving & Low Consumption: No forced circulation pump required, reducing energy costs; low-temperature evaporation protects heat-sensitive components.

·Stable and durable: There are no moving parts, resulting in low maintenance costs. The corrosion-resistant materials are suitable for acidic, alkaline, and saline working conditions. Natural circulation helps to reduce scaling.

·Flexible adaptation: Available in single-effect or multi-effect combinations, with processing capacities ranging from 50 to 5000 L/h. Modular design allows for quick material switching. Intelligent control adjusts evaporation efficiency.

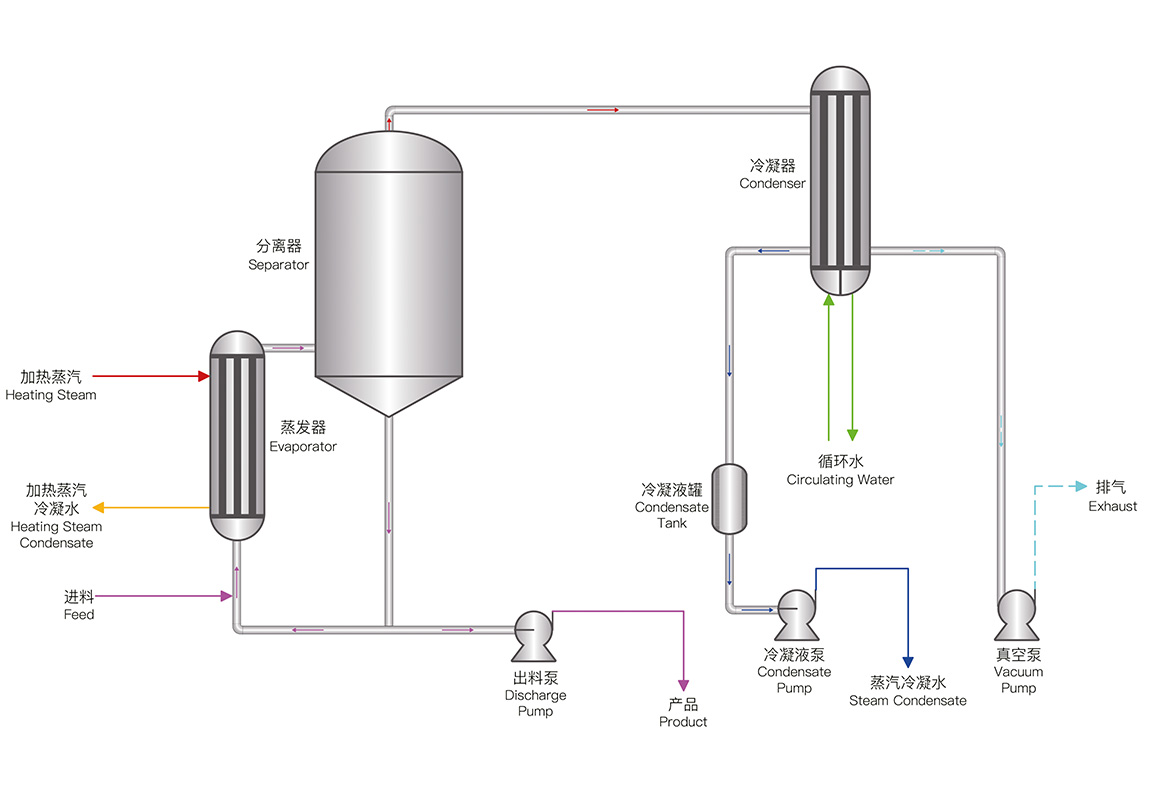

It consists of a heating system, an evaporation separation chamber, a natural circulation pipeline, a vacuum system, and an intelligent control system. The heating system has a tube/plate heater, a foam removal device is installed in the evaporation and separation chamber, and the natural circulation pipeline uses density differences to drive the solution flow. The vacuum system uses a water ring/steam jet vacuum pump, and the intelligent control system is equipped with a PLC interface.

Relies on temperature-driven natural convection without external circulation pumps. The heated material vaporizes to form a vapor-liquid mixture. Vapor is condensed and discharged, while the denser concentrated liquid flows back to the heater due to density differences. Continuous cycling achieves target concentration through repeated evaporation.