Welcome to the 'Online Message' section! If you have any suggestions or questions about our products, please feel free to provide us with feedback through this section.

We will reply to you within 24 hours.

·Strong Adaptability: Suitable for high-viscosity, heat-sensitive, crystallization-prone, and scaling-prone materials.

·Efficient Heat & Mass Transfer: Ultra-thin liquid film maximizes heat transfer coefficient.

·Operational Flexibility: Adjustable parameters (scraper speed, feed flow rate, heating medium temperature) enable precise process control.

·Easy Maintenance: Modular design allows quick disassembly, cleaning, and upkeep.

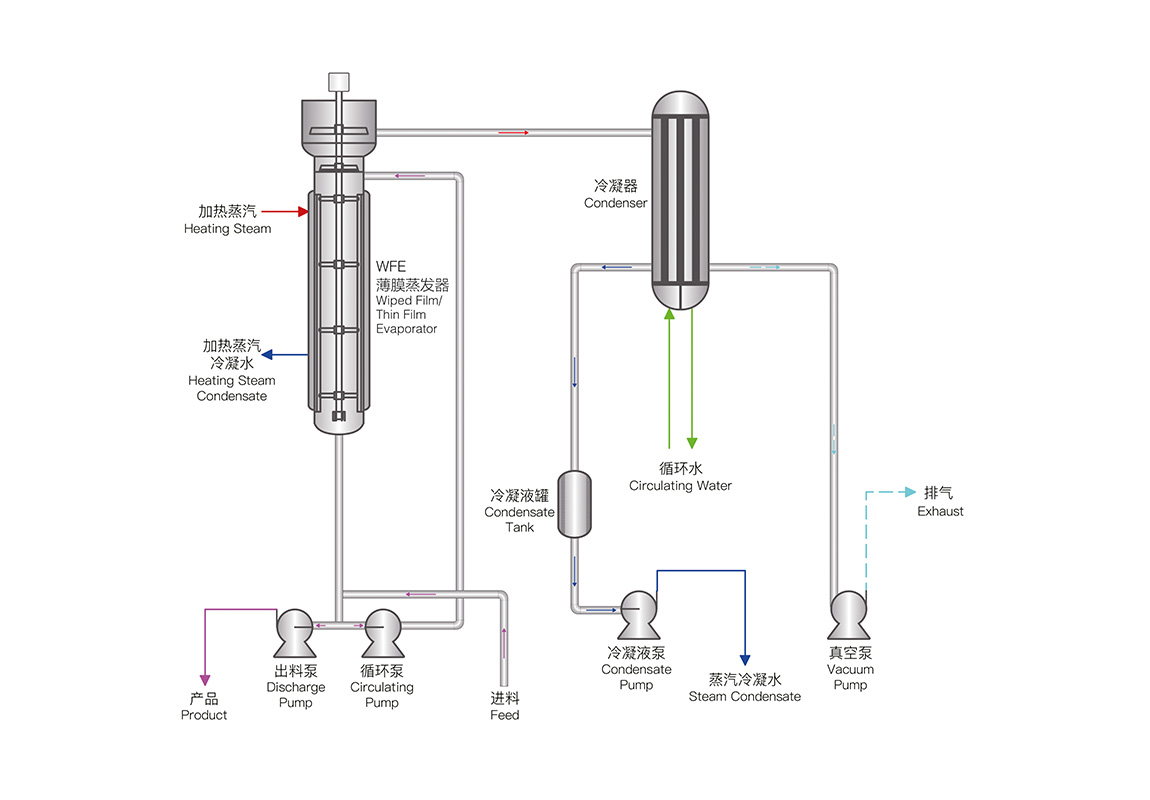

Consists of a heating cylinder, material distribution device, film-scraping assembly, vapor-liquid separator, and discharge system. The heating cylinder features a jacketed structure, with the film-scraping assembly inside driven by an electric motor. The vapor-liquid separator is located at the top of the unit.

Material is fed to a distribution device at the evaporator top, where rotating wipers spread it into a uniform thin film on the heated inner wall. Thermal energy from the heating jacket induces rapid evaporation. High-speed wiper rotation optimizes heat/mass transfer while driving the concentrated product downward for discharge. Secondary vapor passes through a vapor-liquid separator for purification before condensation.