Welcome to the 'Online Message' section! If you have any suggestions or questions about our products, please feel free to provide us with feedback through this section.

We will reply to you within 24 hours.

·Ultra-low energy consumption: The energy consumption is only 30%-50% of traditional equipment.

·Low temperature evaporation: The working temperature can be as low as 30℃ to protect the thermally sensitive components.

·Environmental and clean: No boiler exhaust emissions, meets green production requirements.

·Intelligent control: fully automatic and precise adjustment.

·Compact design: modular design, small footprint.

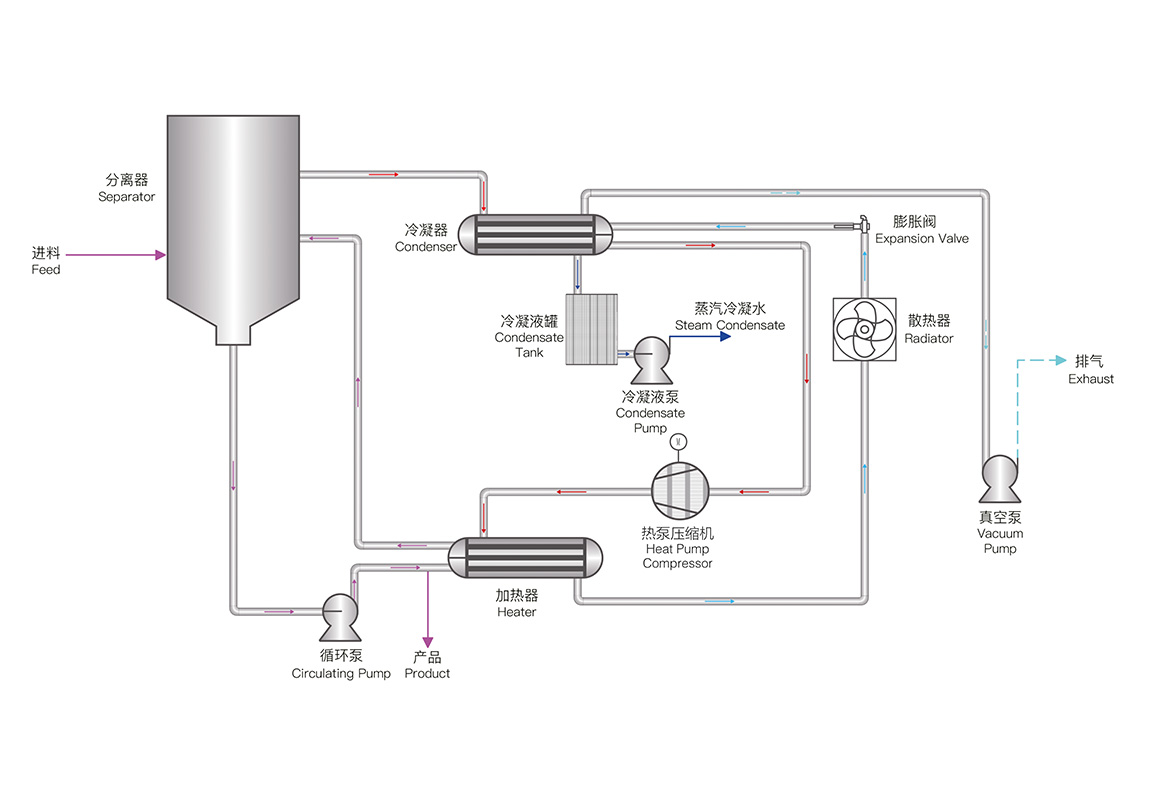

It consists of an evaporator, heat pump compressor, condenser and intelligent control system, and uses high-efficiency heat exchanger and heat pump unit to realize thermal energy circulation.

Material evaporates under low-temperature conditions to generate secondary vapor. A thermal pump compressor upgrades the low-temperature vapor into high-grade heat for reuse in the evaporator, creating a closed thermal cycle. Only minimal electrical energy is required to drive the compressor, enabling high-efficiency evaporation with condensate recovery and concentrated product discharge.